Roald Dahl’s Charlie and the Chocolate Factory is an instant hit with Children. Honestly, Dahl’s endearing style can have anyone hooked. And who can resist an invitation to get into a Chocolate Factory?

Chocolate or otherwise, factories may seem dull and boring to you but they can be interesting places for children to visit. While you may see it as a bunch of machines and people mass-producing something, children see it differently. They love the whirring and whooshing sounds of the machines. They are fascinated to see conveyor belts and other parts, moving, turning, spinning and rotating by themselves. They enjoy looking at things they do not usually get to see. And believe it or not, children have a deep natural sense of curiosity and love to find out how things are made.

So, whether its Ooty and Munnar in the Niligiri Range or Darjeeling and Assam in the North-East that you are visiting, make sure to drop in at the Tea Factory of the Estate.

If you wish to help your child understand how the tea goes from looking like a fresh green leaf to brown dust-like powder, here’s a quick picture-tour that will help you and your child better understand what you see at a Tea Factory. Make sure to double it up with an actual visit to the factory!

The tea is Plucked by women on the hill slopes. They take care to pluck only the first two leaves and a terminal bud by holding the stem between the thumb and forefinger, twisting it for a clean snap. (Why only women? Click here for more)

The women take the tea they have collected in their baskets and go to the weighment sheds where they are Weighed and recorded. You will spot little open tin-roofed structures around the farm which have large portable hanging scales with a hook to suspend the plucking basket. Here is where the supervisor ways and records how much each one has collected.

Heaps of the leaves are then Loaded onto small tractor-trailers and carted up narrow steep dirt roads to the on-site factory for further processing. The Tea Factory is always located within the tea estate for the tea must be processed immediately after it is plucked. The quicker it is processed, the fresher is the tea.

The tea leaves are Transported to the factory in a vehicle. The factory is a largish building which is about two stories tall with high ceilings. It has a number of machines and a few people who attend to the machines. Here, the leaves will be processed and become finished tea within 24 hours.

As one enters the Tea Factory, one cannot help but notice the strong smell of crushed tea leaves and the gentle whirring sounds of the machines.

The freshly picked leaves are first taken for Withering. They are spread out evenly on long narrow wooden troughs with fine wire mesh bottoms through which air blows. They pass through this for about 14 to 16 hours during which time the leaf is completely dried and begins to wilt and turn. The colour changes from bright green to shades of olive green and brown. The leaves also soften and become limp so that they can be rolled without breaking. By touching the leaves and inhaling its fruity smell, an experienced factory worker will know whether the correct wither has been reached.

Next, the leaves are gathered and dropped down a square hatch through a cloth shute to the floor below to meet the rolling machines. Rolling was a process that was earlier done by hand but now done by machines. Here, the leaves are placed on a saucer like table which gyrates to twist and curl the leaves without breaking them. This process is constantly watched over by a factory worker to ensure that the leaves don’t get too warm from the friction or rule to tight. This takes about 15 to 90 minutes depending on the condition of the leaves, the weather and the desired strength of the tea. A longer role would mean more pressure on the leaves and give more colour and body to the tea. Rolling ruptures the cells of the leaf, forcing the release of its natural juices.

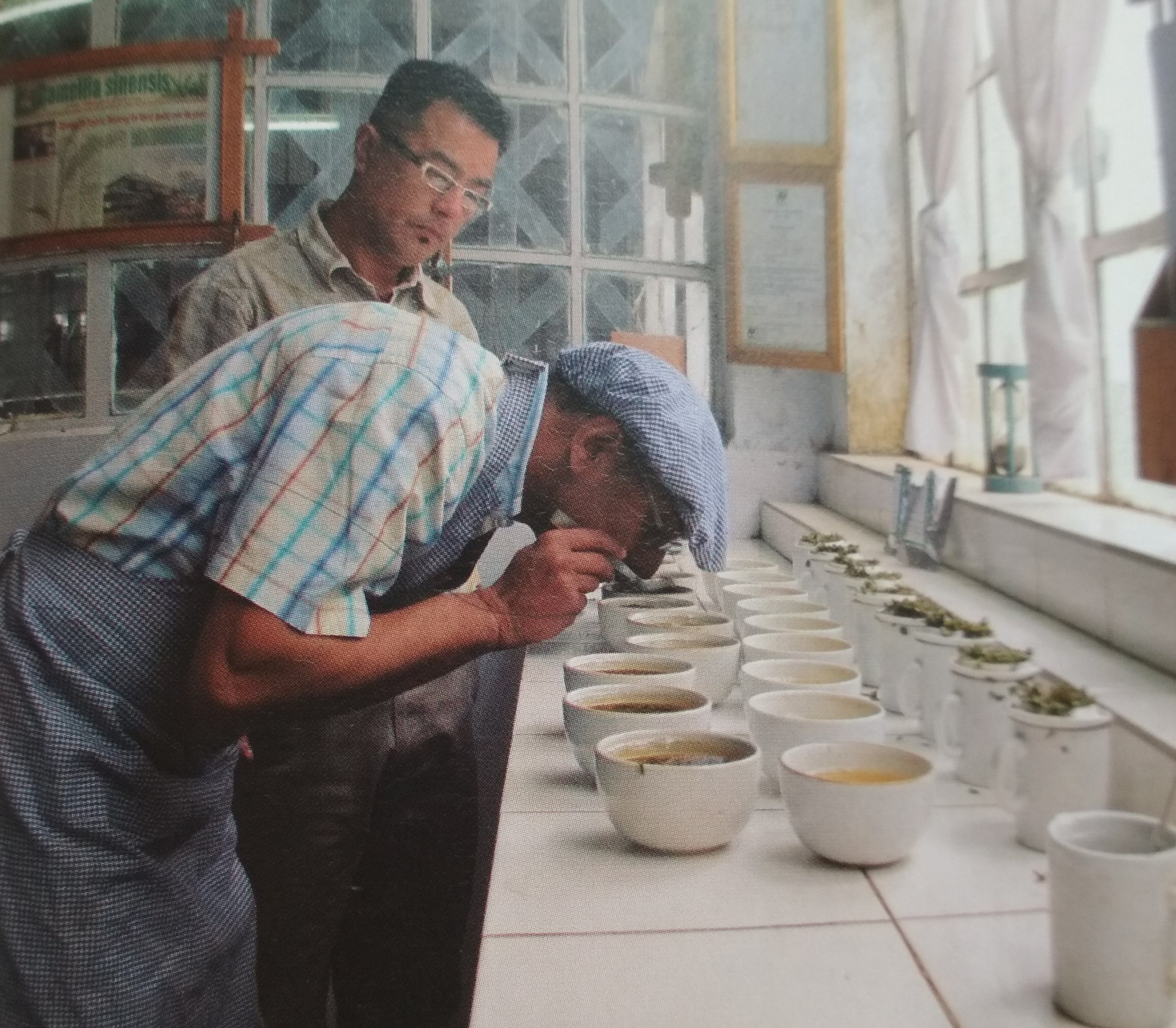

Rolling lays the ground for Fermentation. Here’s where the tea develops its aroma and strength. The tea is placed on portable sheets of steel which are stacked on top of one another which are called fermentation tables. The workers spread out the leaves in a thin layer so that they get plenty of air. This air is necessary to ferment or oxidise the tea and here’s where it acquires its coppery brown colour. You will find a factory worker constantly scooping up a few leaves, to check the progress of fermentation by smelling them. It is only experience that teaches a worker to gauge from the smell whether the fermentation process is complete or not. No other can teach this skill!

Next, workers tip the fermented leaves into the dryer’s Hopper where a conveyor belt slowly zigzags from top to bottom in about 240°F air where the tea slides by to allow the last bit of moisture to get sucked away. Again, it is necessary to ensure that the duration is regulated as the tea would get overly crisp or dry out too much, killing its flavour.

Sorting is the next stage you will see at the factory. The tea is sorted into four different categories – Whole Leaf, Broken Leaf, Fannings and Dust. Sorting is done both by machine and by hand. Vibrating machines push the tea leaves down a narrow ramp as the tea falls through perforated gaps into collecting bins. The perforations get progressively smaller and finally only the tea dust remains. Like plucking, sorting too is done exclusively by women

Grading is the final stage before the tea can be shipped out of the factory. While in most tea factories, the first-grade tea is reserved exclusively for the export market, fannings and dust are usually kept aside to fill tea bags. The sorted tea is weighed and filled into boxes/packets and makes its way on trucks to warehouses from where it will reach the next stage of its journey and finally into the hands of the drinkers.

Tea Factories usually have a Tasting Room where you can taste the various grades of Tea processed at the factory. This too, can be an interesting experience where you can get your child to test out the different varieties and tell if they can spot any differences between them.

I have taken my children to tea factories –at Munnar and at Ooty. They enjoyed both visits and learnt much – not just about tea and factories but also other incidental things. They learnt that a machine could do the work of several people – leading to joblessness and possible resentment. They learnt how fuel powers machines at factories and how essential it is. They understood the effect of heat and moisture. They understood how industrial processes could dramatically alter the nature of things. You can tell them much more.

For more interesting snippets, ideas and stories to make the most of your visit to a Tea Estate, click here, here and here!

.

Trackbacks and Pingbacks